Standard or hybrid screen Calibration test for flexo

It is the perfect tool to set your dot gain compensation curve at the first step of the order through our configurator when you buy your flexo plates on Flexo 24. Order your test and you will receive:

- one photopolymer plate with the parameters that you set in the “Utility” tab when you placed your order.

- The related FOGRA39 table.

- A promotional code of € 25,00 that you can use in your next order.

Take advantage of the highest professional service guaranteed by Flexo 24.

The market value of the Calibration test for flexo is around € 400,00. With Flexo 24 you can buy your kit to set the real compensation value for your printing system for only € 25,00 (you will get a refund* of this amount in your next order.)

What can you check by printing your test?

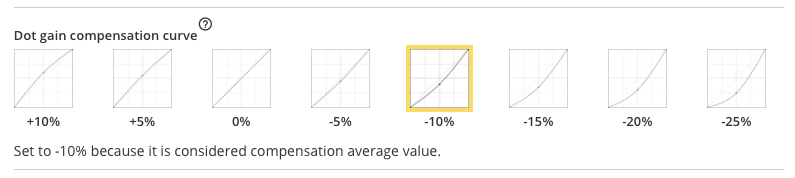

It is important to understand how your flexo system works with the screen ruling that you want to use. Check the correct value between +10% and -25% when you select your photopolymer digital plate in Flexo 24.

The calibration test is easy to use.

How can you buy your standard or hybrid screen test?

Fill in the text in the box that you find in the “Utility” tab:

- Substrate: paper and paperboard, plastic film, aluminium and adhesive paper, carton or tissue.

- Ink: water-based, solvent-based or UV.

- Plate thickness: 1,14; 1,70; 2,54; 2,84; 3,94; 4,32; 4,70; 5,00; 5,50 mm.

- Resolution: 2540 or 4000 dpi.

- Hybrid screen: yes or no.

- screen ruling: from 19 lcm to 65 lcm for 2540 dpi and from 39 lcm to 88 lcm for 4000 dpi.

- Size: width x height of the plate in mm.

By default the

screen is circular

How to use a standard or hybrid screen test?

When you receive your 32 x 40 cm TEST plate and the related FOGRA 39 TABLE:

- Print with the TEST plate on your substrate.

- Compare the printed values and images with the FOGRA 39 TABLE.

- Find where the images and fingerprints that you printed in the TEST match the FOGRA 39 TABLE.

- Check what is the dot gain percentage of the selected printed image.

- Use this dot gain compensation value on your next order.

With this test you will decide what is the optimal dot gain compensation value for your flexo system and proceed with the order of the plates.

KODAK calibration test.

The test is described in the article “Kodak flexo plates: more than 6 reasons to choose them”. This test will show you which of the 6 available KODAK NX patterns you should use (+1 “no pattern”):

- Standard

- Advanced 01

- Advanced 02

- Advanced 03

- Advanced 04

- Advanced 05

- "No pattern"

How can you buy your KODAK calibration test?

Fill up the form in the UTILITY section:

- Substrate: paper and paperboard, plastic film, aluminium and adhesive paper, carton or tissue

- Ink: water-based, solvent-based or UV

- Plate thickness: 1,14 mm.

- Resolution: Kodak NX dpi

- Screen ruling: from 17 lcm / 44 lpi up to 82 lcm / 208 lpi

- Size: width x height of the plate in mm

How to use a KODAK calibration test

Print on the substrate with your TEST plate using one of the three primary colours: cyan, magenta or black plus a full coverage ink (for example white or Pantone). We recommend using a softer tape to improve the uniformity of the printed result. Once the material will be printed, check what is the Kodak NX pattern with the best results as to density, coverage and sharpness of the screened areas.

Benefits of the test.

In the packaging industry it is essential to reduce any possible waste of time and resources. With the flexo calibration test you can optimise now your plates and you will not need any test prints of details or full tones reducing the possibility of errors in the production workflow. You will also reduce material waste, contributing to preserve the environment.

(*) Receive now a discount of € 25,00 for orders above € 199,00.