Flexo dots: Hybrid or Circular? Flexo 24 is the answer.

Flexo dots: Hybrid or Circular? Flexo 24 is the answer.

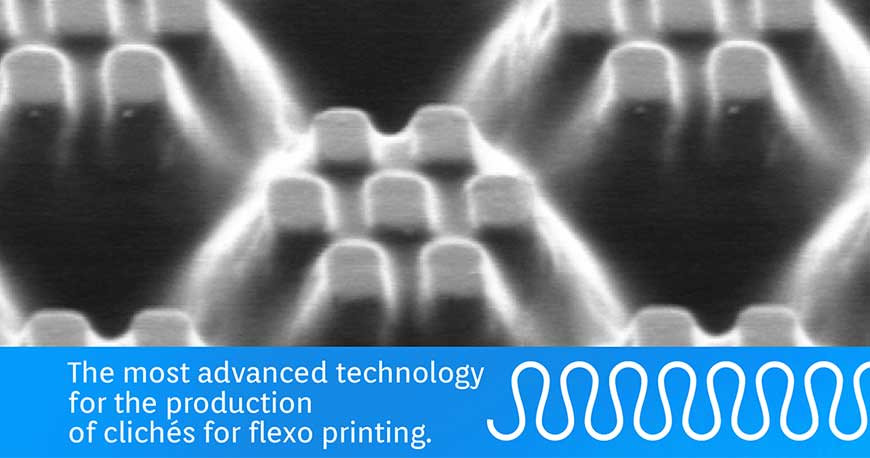

Flexo dots, minimum dot and new 2022 functions to support the experience of the professionals in the market of flexo printing and packaging.

Starting from the customers’ requirements, Flexo24 keeps constantly up-to-date to prove the best choice for their projects to print packaging. Flexo technology is demanding skilled support for solving any problems during the printing process, as we also explained in the article Flexo printing: the top 12 mistakes and their solutions.

Application of the minimum dot.

The engraved dots should have a minimum size according to the specifications of the plate material. The “bump-up curve” function ensures that all the engraved dots have the same minimum dimension allowed; below these dimensions flexo plates might be unstable and show non-printing areas.

Especially by projects with a high dotgain value, we can have in rare cases an undesired effect of interruption of the shade, commonly known as “crusty” or “ripping” effect. One strategy to overcome this limit is the use of hybrid screening.

PRO TIP

Using hybrid screen helps avoiding the “ripping” effect. The percentages below the minimum printable dot are created through a dot with the same dimension as the minimum printable, but displayed randomly like in a stochastic screen.

Thus, we can have an optical effect of transition to 0%, but still keeping the minimum printable dot for that specific plate.

The transition spot from conventional to stochastic is directly proportional to the line count. The higher the screen count, the higher will be the transition spot positioned.

CALIBRATION TEST

KODAK or HYBRID.

Press the button to request your

calibration test with REFUND.

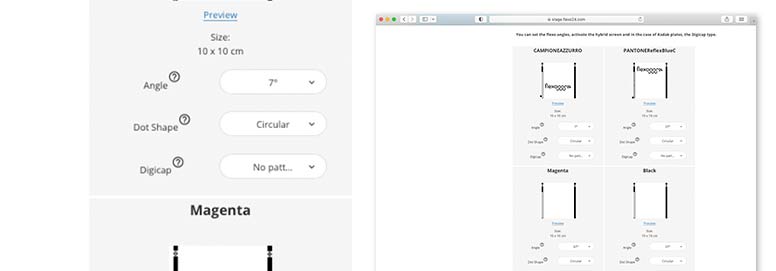

Flexo angle, circular and hybrid dot.

After the PDF file is processed by Flexo24’s software, the file preview will be loaded and the operator will be enabled to set angle, dot type and Digicap as shown in the image below.

Angle.

The engraving direction of the screen dots in flexo should have an angle of 7°, 67°, 82° or 37°. The difference between the angle of the screened areas of each color should be 30°. Yellow deviates by 15° from Cyan and Black to avoid the moiré effect that we already described in this article.

Protip

When using the 82° angle, the best choice would be to apply it to the lightest color. As from the ISO 12647-6:2012 standard for flexo, the nominal difference between the angles of Cyan, Magenta and Black should be 30°, while 15° for Yellow, the lightest color.

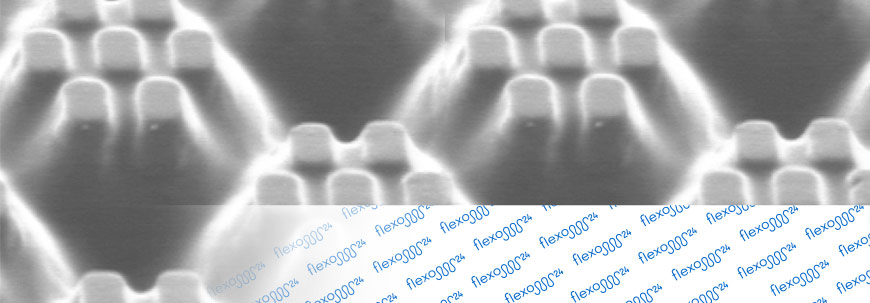

Circular dot (Esko Euclidean).

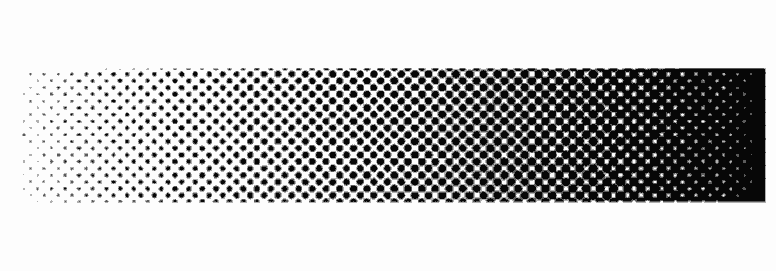

The circular flexo dots are the most popular type in flexo printing: the shape is continuously circular..

The image shows how the dots are engraved. Right, the cooler density is 100%, that is full color. Left, 0% means no engraving, no color from the PDF file.

From no color, i.e. engraving density 0% (left), the dimension of the circular dot increases up to a 100% density (right). From around 75% the circular dots start to intersect: they will gradually merge until 100%

Protip

The circular dot is a default setting in Flexo24: to change this, the operator must select other choices. For more information check Esko’s official documents.

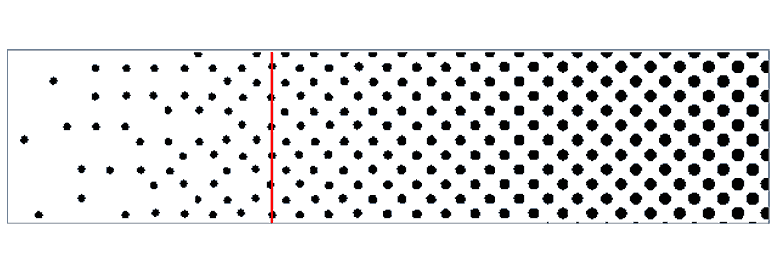

Hybrid dot (Esko Autoblend).

The engraved flexo dots are scattered on the plate. Such layout starts from a color density that varies according to the screen count and the type of plate. Below 5% color density, dots are displayed unevenly (unlike the circular dot which is randomly displayed instead).

The red line in the image above indicates the transition between:

- circular layout (right),

- hybrid layout (left).

All dots have the same size but they are displayed randomly: as the color density tends to 0%, the dot frequency in the layout gets lower. On the right of the red line the screen count remains the same while the thickness of the dots increases together with the color percentage.

The hybrid zone is only from 0% to the transition spot: the red line. The minimum, smallest printable dot depends from the plate specifications. For example, for the Asahi DEF 1.14 mm plate the minimum printable dot at 4000dpi is 50 microns large.

Protip

Using 59 lcm / 149 lpi screen, the transition point from hybrid to circular is about 7%. While, if the screen is 34 lcm / 87 lpi, the dot becomes circular at about 2.4%. This is because at lower screen rulings, the circular screen dots are larger than those engraved with higher rulings.

CALIBRATION TEST

KODAK or HYBRID.

Press the button to request your

calibration test with REFUND.

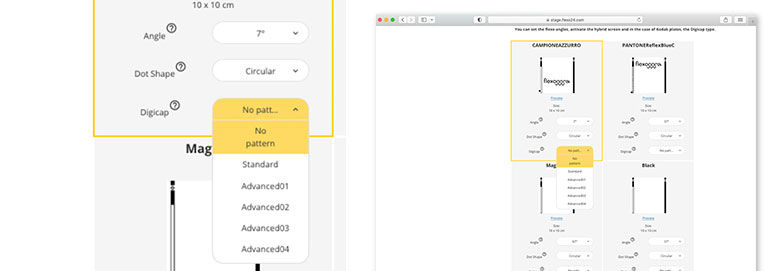

Kodak Digicap NX algorithm patterns.

As soon as the pdf is loaded, the exclusive Flexo 24 software gives you back the previews. And, if the resolution is set to "Kodak NX dpi", the type of Digicap technology will be requested. ("No pattern" sets by default). This is the type of pattern to use, derived from the Kodak calibration test.

Selectable from the following:

- No pattern.

- Standard.

- Advanced01.

- Advanced02.

- Advanced03.

- Advanced04.

- Advanced05.

** ONLY WITH FLEXO24 ** it’s possible to choose the possibility of NOT engraving the points according to the Kodak Digicap, with "NO PATTERN" option, also used to print with UV inks. In this way no pattern will be applied Kodak.

Protip

The screens, or Circular or Hybrid type of point, have no relation with Kodak patterns. We have published an article about it.

You can consult the following table which indicates the type of Kodak pattern recommended in relation to the anilox roll. It is depending on the volume of ink carried by the roll:

CALIBRATION TEST

KODAK or HYBRID.

Press the button to request your

calibration test with REFUND.

Duplicate the single order by the Shopping cart.

On the shopping cart page, the “+” sign duplicates the plate, or groups of plates. With the same specifications and the same graphics as the PDF. Saving time with the same reliability.

On the shopping cart page, the “+” sign duplicates the plate or groups of plates. With the same specifications and the same graphics as the PDF. Saving time with the same reliability. #Flexo24 #Packaging #label #Digital pic.twitter.com/vQsgGGN0bz

— Flexo24 (@theFLEXO24) April 19, 2022

Save the settings.

It’s the possibility to recall the configuration with a click instead of setting it at each loading.

Flexo 24 is technology to the next flexo printing.

Flexo 24 is always being updated and 2021 was also an excellent time to develop new functions from the feedback of the market from packaging printing professionals, making the service more affordable: