The future of flexography is now

1st order -15% DISCOUNT>>

1st order -15% DISCOUNT>>

Create your account and

Company access

The service for the packaging Companies

Flexo24 has been born for over 40 years

of experience in the flexographic sector.

Today is the innovative ONLINE service

exclusive for Companies in the packaging supply chain.

LOGIN

of experience in the flexographic sector.

Today is the innovative ONLINE service

exclusive for Companies in the packaging supply chain.

Flexo for the environment: because care is never enough

Flexo for the environment is committed to waste as little resources as possible and not to release any harmful substances into the ecosystem.

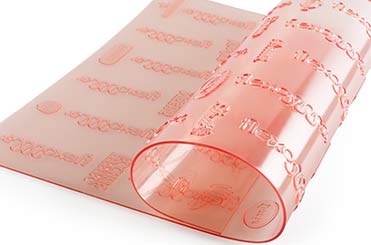

From the exclusive two Vianord automated lines for the development of flexo plates (which include wash-out, drier, finishing unit, stacker and the storage area), Flexo24 recovers all platemaking solvents with a double filtration system.

To do this, the company is equipped with two systems:

To do this, the company is equipped with two systems:

- - The first, a chiller, is intended to induce a thermal shock to transform vapour into dew. This step allows to recover part of the platemaking solvent to obtain dry air.

- - The second system filters dry air with activated carbon filters to restore air purity. All substances separated among the various phases are then recovered.

Flexo products.

Flexo for the environment reduces resources waste

The system for recycling the solvents of the platemaking process.

Flexo for the environment means passing a better planet on to our children by using technology as a way of reducing resources wastage and optimizing the energy used for both employees and production.

Flexo24 has made a commitment to use eco-friendly materials also for promotional gadgets.

Flexo for the environment uses a sophisticated air filtration system

The filtration system for the air coming from machines and engraving of the digital plate.

The experience since 1986 in the use of machines for the development of flexo plates, photopolymer plates, has led to an articulated filtration system.

Flexo24 connected to its production lines a sophisticated activated carbon filtration system that can filter air and recover solvents used in the production process.

This reduces atmospheric emissions and eliminates residues of harmful substances. It also allows employees to work in a better environments and to pass on a more liveable planet to our children.

Zero impact energy

Double result with two solar energy systems.

With the aim of respecting the environment, Flexo24 installed two photovoltaic systems at the production unit in Roncade near Treviso: the first in 2010, supplemented by the second in 2012. These systems make it possible for the company to meet most of its energy needs.

Clean energy, available all year round, at zero impact.

"More than ever before, now we must live in an environmentally sustainable way because only then can we aspire to pass on a legacy of better environment. To do this, we must first preserve our resources, avoiding any waste."

(Diego Di Muro, Flexo24 CEO)

(Diego Di Muro, Flexo24 CEO)

For this reason, Flexo24 installed a sophisticated activated carbon filtration system at its production unit that filters air and recover solvents used in the production process:

- - The first, a chiller, is intended to induce a thermal shock to transform vapour into dew. This step allows to recover part of the platemaking solvent to obtain dry air.

- - The second system filters dry air with activated carbon filters to restore air purity. All substances separated among the various phases are then recovered.

Warranties

CONAI

For its packaging, Flexo24 uses only recycled cardboard. The eco-sustainability factor is no longer just a niche issue: more and more companies are becoming aware of environmental issues.

Double result with two solar energy systems.

With the aim of respecting the environment, Flexo24 has installed two photovoltaic systems at the production unit of Treviso, Italy.

The first in 2010, integrated by the second in 2012. These systems allow the company to satisfy most of your energy needs while respecting the environment at all times.

Consult the current state of energy production from the sun:

The first in 2010, integrated by the second in 2012. These systems allow the company to satisfy most of your energy needs while respecting the environment at all times.

Consult the current state of energy production from the sun: